QMS - Certified

Precision is not a milestone it is a standard.

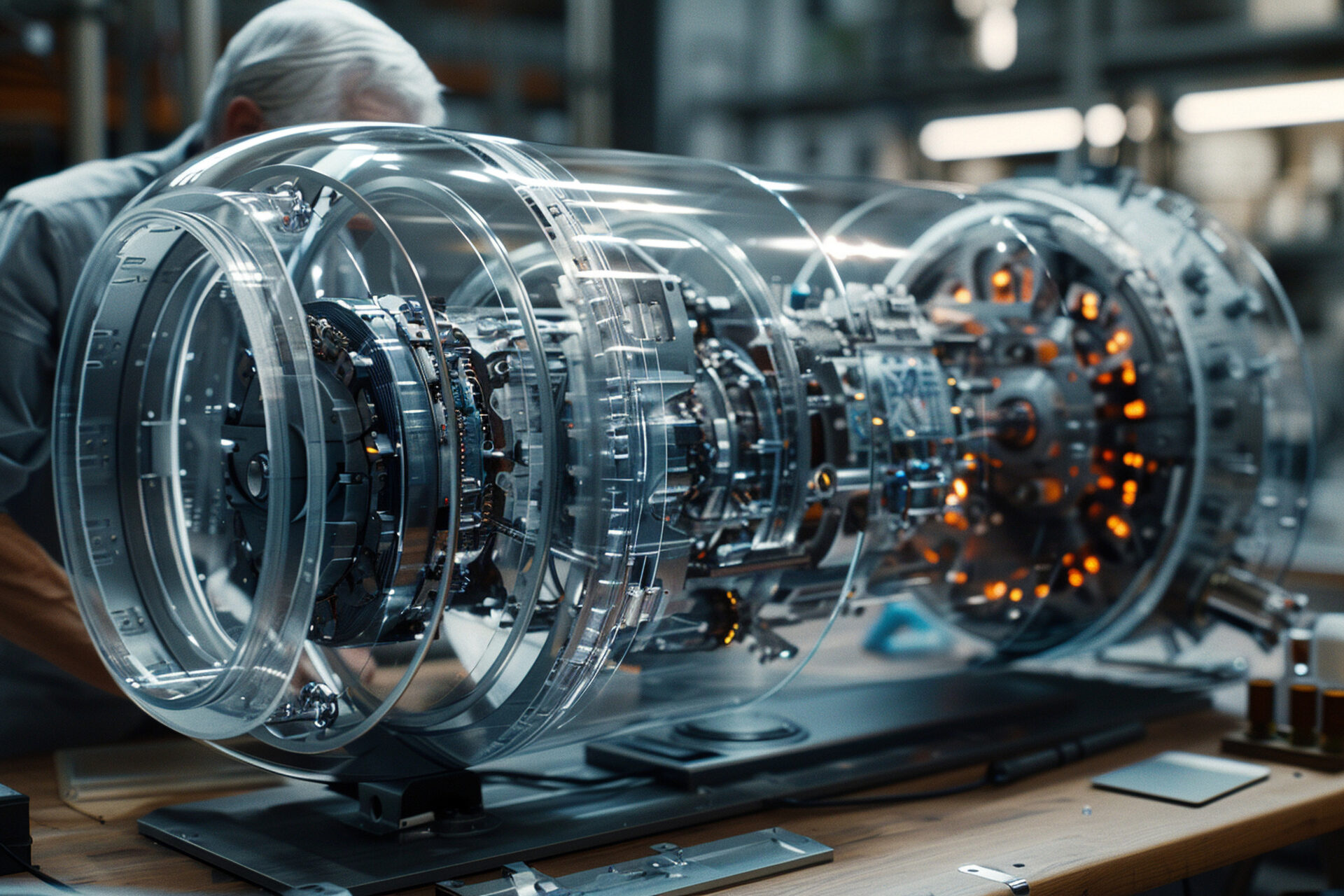

Lyncus empowers strategic missions in advanced, complex and challenging environments for high-priority industries spanning global aerospace, medical, and industrial engineering with accurate, high-performance components and assemblies engineered for critical applications.

Capabilities

Specializing in the manufacturing of engine components, complex assemblies, inspection fixtures, and precision tooling for OEMs, Tier-1 suppliers, and global integrators, the core capabilities of Lyncus includes:

These are supported by in-house special processes such as heat treatment (HT) and brazing, to ensure structural and metallurgical integrity for high-performance builds.

Apart from providing domain expertise in non-conventional machining (EDM) and honeycomb seal assemblies, Lyncus has also extended its operations to chemical processing that supports vertically integrated manufacturing for aerospace, medical and other industries.

Infrastructure

Operating from a 65,000 sq. ft. state-of-the-art facility, Lyncus is fully-outfitted to manage aerospace-grade materials with tight tolerances, and complex geometries delivered with total transparency and repeatability, smoothly transitioning from prototyping to full production volumes.

➧ Centre of Excellence focused on:

➧ Designed to house R&D, prototyping, and advanced manufacturing under one roof; Positioning Lyncus as a fully integrated precision manufacturing hub.

➧ Varshik Merged: Unified machining, sheet metal, and welding operations under one brand Lyncus.

➧ Signed-Up for Unit2: 65,000 sq. ft. space to develop state-of-the-art facility

➧ LTA’s with Tier 1 aerospace customer for precision machined parts and inspection gauges.

➧ Launched NADCAP certification program

• for Fusion & Resistance Spot Welding

• Internal team mobilized for audit readiness by November 2025

➧ Achieved AS 9100 certification, demonstrating high standards in aerospace quality management.

➧ Secured major orders from OEM for sheet metal fabrication.

➧ Broadened presence in the global aerospace supply chain, establishing credibility with new international clients.

➧ Formed a strategic alliance with Varshik Engineering, expanding capabilities into:

• Sheet metal fabrication

• Welded assemblies for complex structural part.

➧ This move diversified offerings and positioned the company for integrated manufacturing.

➧ Company was incorporated as a precision machining facility, marking its entry into high-accuracy component manufacturing.

➧ Started with limited-capacity CNC machining, focusing on prototypes and low-volume precision parts.

➧ Focused on tight-tolerance parts for aerospace and automotive applications.

➧ Centre of Excellence focused on:

➧ Varshik Merged: Unified machining, sheet metal, and welding operations under one brand Lyncus.

➧ Signed-Up for Unit2: 65,000 sq. ft. space to develop state-of-the-art facility

➧ LTA’s with Tier 1 aerospace customer for precision machined parts and inspection gauges.

➧ Launched NADCAP certification program

• For Fusion & Resistance Spot Welding

• Internal team mobilized for audit readiness by November 2025

➧ Achieved AS 9100 certification, demonstrating high standards in aerospace quality management.

➧ Secured major orders from HAL Engine Division for sheet metal fabrication.

➧ Broadened presence in the global aerospace supply chain, establishing credibility with new international clients.

➧ Formed a strategic alliance with Varshik Engineering, expanding capabilities into:

• Sheet metal fabrication

• Welded assemblies for complex structural part.

➧ This move diversified offerings and positioned the company for integrated manufacturing.

➧ Company was incorporated as a precision machining facility, marking its entry into high-accuracy component manufacturing.

➧ Started with limited-capacity CNC machining, focusing on prototypes and low-volume precision parts.

➧ Focused on tight-tolerance parts for aerospace and automotive applications.

At Lyncus, our culture blends engineering excellence with human dedication. We foster a workplace where precision meets collaboration, and every team member is empowered to contribute and grow. Safety, integrity, and continuous improvement guide our every move. Together, we build more than parts – we build trust, innovation, and lasting impact.

We believe that a strong culture drives strong results. Our team thrives in an environment that values craftsmanship, accountability, and innovation. From the shop floor to the leadership team, we work with a shared commitment to quality, efficiency, and mutual respect. It’s this unified mindset that keeps us advancing forward together.

Skilled hands, sharp minds, and a shared commitment to doing things right every time.

Building strong relationships with customers and strategic suppliers , leveraging each other's strengths to achieve remarkable results, solve problems and create opportunities for success

Fostering enduring relationships rooted in expertise and integrity.

Adapting alongside clients, partners, and global markets to effectively meet the challenges of a rapidly changing precision ecosystem.

We foster a culture where quality is everyone’s responsibility from the shop floor to leadership. Every process, decision, and detail reflect our collective commitment to excellence.

We don’t just adapt - we lead, driven by focus, precise execution, and uncompromising standards. Discipline isn’t a practice; it’s our organizational DNA

Lyncus partners with diverse, global network of customers, vendors, suppliers, and stakeholders in aerospace, medical, and critical industrial sectors to deliver customized manufacturing solutions that meet the highest international standards. Prioritizing precision, performance, and long-term value, this dedication continues to earn the trust of industry leaders

Our vision is to set the global standard in precision manufacturing, delivering innovation, excellence, and reliability

© Copyright 2025. All Rights Reserved By Lyncus. Designed by Digju.com.